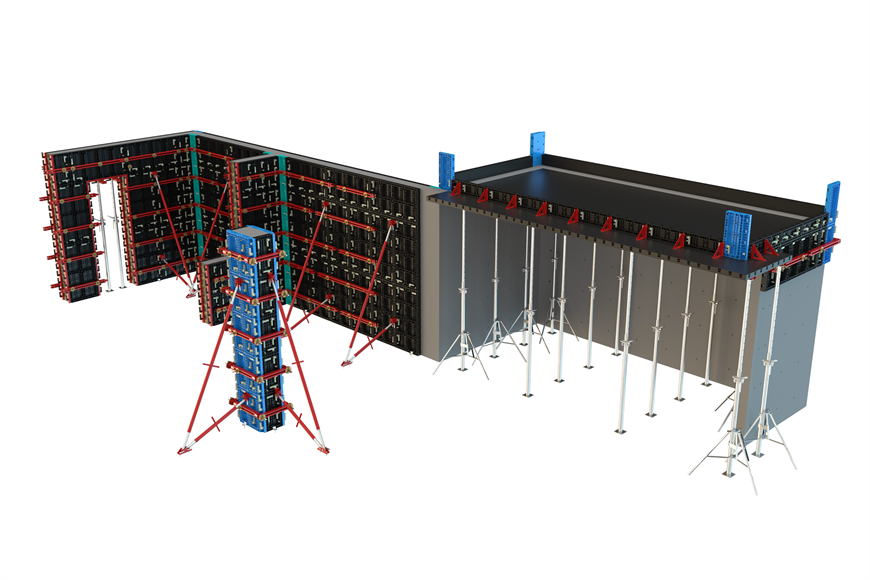

MAUP Plastic formwork is made from ABS or PP with fibreglass. It is the lightest system among all other material formwork systems.

We have Plastic Formwork TP60+, Plastic Adjustable Column Formwork and Plastic Round Column Formwork right now for your option. With daily productivity of up to 40sqm/person, it has wide application areas such as remote areas where construction machines can’t go or project sites with no crane available.

The plastic formwork system is made of a specific grade of plastic, neither placing any attached material nor chemical reaction between the poured material and the plastic formwork. Therefore, the surface of the reinforced concrete element will not have any spots.

Due to the perfect adaptability of each part of the system, the leakage of water or newly poured concrete from different parts is avoided. In addition, it is the most labour-saving system because it is easy to install and insert and lightweight compared to other formwork systems.

There is no need to nail and lubricate the board before pouring concrete because the automatic levelling of the plugging system can automatically level the board, so compared with the traditional formwork system, the time spent during installation and disassembly is reduced.

In addition, the plastic concrete formwork can be easily washed with water after use. If it breaks due to improper handling, it can be sealed with a low-pressure hot air gun.

Other formwork materials (such as wood, steel, aluminium) will have various disadvantages, exceeding their benefits. For example, wood is quite expensive and has a significant impact on the environment due to deforestation.

For plastic formwork, it can be used many times. However, because the plastic formwork price is higher than some other types of formwork, it is wrong in many cases. In contrast, plastic formwork can be recycled, and in addition to reducing processing time and improving reusability indicators, it is also environmentally friendly.