Quality is our eternal promise to the customers. Safety, nice appearance, stable performance and long service time are the primary factors to qualify MAUP products.

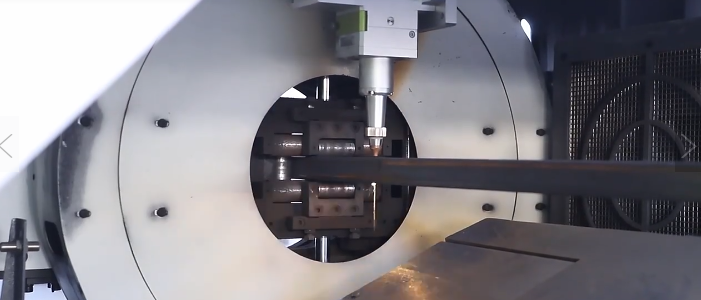

Our products comply with different standards. GB standards of welding, pressing, punching, casting, and forging for other parts are adapted accordingly, while EN standards (EN1065, EN13377, etc.) are also adapted in our key components.

Quality is the cornerstone of our business. The quality of our products ensures their longevity when this is appropriate and ensures the safety of the workers on construction sites. All our products comply with the different standards depending on their production.

Our products comply with different standards. GB standards of welding, pressing, punching, casting, forging for other parts are all adapted accordingly, while EN standards (EN1065, EN13377 etc.) are also adapted in the production of our key components.

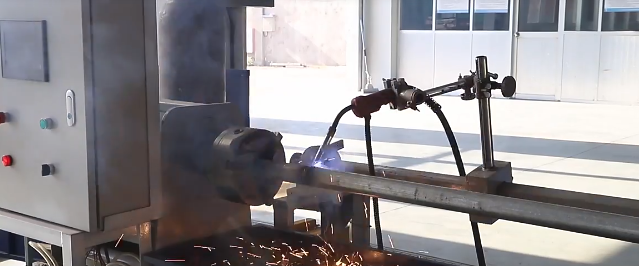

For all sizes of products from tie rods to self-climbing formwork brackets, for items produced in our workshops or outsourced from others, we have an over-arching Quality Control System which runs throughout the whole process of order delivering, from incoming raw materials inspection, manufacturing process inspection until the final finished products inspection.

For system formwork such as self-climbing formwork, climbing formwork, dam formwork, protection screen, single side wall formwork etc., the MAUP QC team always make mockups in the yard before shipment to ensure smooth assembly when materials are sent to the site.

As well as internal quality control from production to inspection, we work with a third-party laboratory for the load capacity test, certification or pre-shipment inspection, all to make products reliable and better.

"We are always proud and confident to say, MAUP materials successfully maintained much better appearance and performance in the past years and will continue its excellence in the new decades.", our Chief Engineer Reed Liu said.

For any item small like tie rods or significant as self-climbing formwork bracket, and for any item produced by own workshops or outsourced from others, we have a corresponding quality control system which strictly runs throughout the whole phases of order delivering, from incoming raw materials inspection, manufacturing process inspection till finished products inspection.

For system formwork such as self-climbing formwork, climbing formwork, dam formwork, protection screen, single side wall formwork etc., the MAUP QC team always mockup in our yard before shipment to ensure smooth assembly when materials send to the site.

Despite internal quality control from production to inspection, we also work with a third-party laboratory for the load capacity test, certification, or pre-shipment inspection to make products reliable and better.

"We are always proud and confident to say, MAUP materials successfully maintained much better appearance and performance in the past years and will continue its excellence in the new decades.", our Chief Engineer Reed Liu said.